Introduction

If your car has a turbo and you want to keep it healthy, then this article is for you. Everyone knows that maintenance is important on cars, it goes back to the age old saying that if you take care of a tool, it’ll take care of you.

Preventative Maintenance

A perhaps lesser-known fact is that preventative maintenance is even more important regular maintenance (oil changes, tire rotation, etc.), preventative maintenance seeks to address and prevent problems before they happen. This could be something like replacing a head gasket because you either know that your car is old or because you know it’s a common point of failure for your engine. You are performing maintenance (changing the head gasket) to prevent a problem (blown head gasket) from ever occurring.

When done correctly preventative maintenance can make any engine reliable. It requires the owner of the vehicle to be aware of both the failure points of the engine and how they treat the engine. For example, let’s say that you have tuned your car to have more boost, then a preventative maintenance step could be to consider upgrading to forged internals to help the engine cope with the added pressure.

Preventative maintenance is also more important in forced induction engines, as they have more points of failure. But before moving forward, let’s quickly talk about what forced induction is and how it works.

Forced Induction

So a normal engine is what we would call a naturally aspirated engine (read my article about naturally aspirated engines here), these engines naturally ingest air and have no way of forcing more air into themselves. Typically, these engines are found on most base model cars though in recent years they have been increasingly replaced by small displace turbo engines.

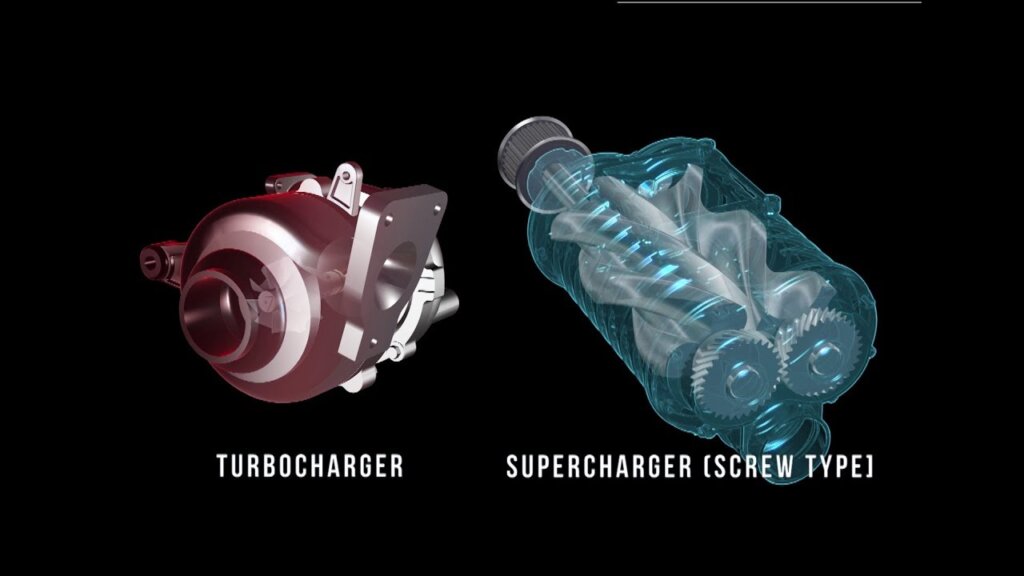

A forced induction engine forces uses some method to force more air into the engine than a naturally aspirated engine. Getting more air into the engine is typically accomplished through either a turbocharger or supercharger, both of which are devices that can compress air.

Turbochargers are propellors that are spun or spooled by the exhaust gases of the engine, as they spin, they force more air into (therefore compressing air into) the combustion chamber. Superchargers are driven by the engines belt, so as the RPMs climb, the supercharger spins and compresses air into the combustion chamber.

Combustion

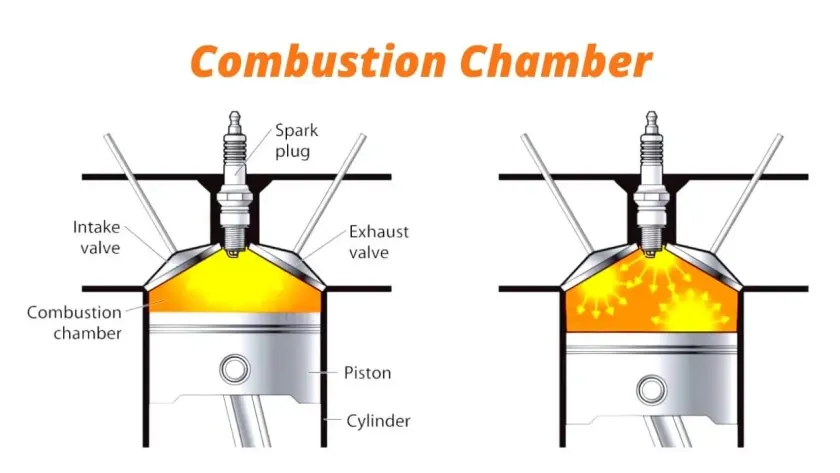

Now you may be asking why it is so important to get more air into the combustion chamber, answering this question takes a little bit of chemistry knowledge. The engines we use in cars are called internal combustion engines; they’re called that because they perform combustion inside themselves. The combustion is the ignition of fuel in the combustion chamber, and the energy from that explosion allows the engine to generate power.

So it then follows that if we can get more energy out of that explosion, the engine can make more power. To get more energy out of combustion, we can add more fuel and more air. Getting more fuel in there is easy enough, we can use high pressure fuel pumps and bigger injectors along with a tune. But how do we get more air in there? That’s what forced induction is for, we used forced induction to compress more air into the combustion chamber and create bigger explosions than we could with a naturally aspirated engine.

The Most Important Preventative Maintenance on Turbo Engines

Ok now you understand what forced induction is, roughly how it works and why we use it. What you don’t know is why any of this matters in the context of preventative maintenance.

It should be clear to you now that a forced induction engine has more moving parts than a naturally aspirated engine – which means more points of failure. This is what makes preventative maintenance more important in forced induction engines.

As forced induction motors are compressing large amounts of air into the combustion chamber, it is important to ensure that there aren’t any blocks in the intake system. We want to have an airflow from the intake to the engine that is as smooth as possible. There is one item in particular that stands in the way of that airflow, it is the air filter.

Initially the air filter may sound like a not so important part of your engine, but it is a huge failure point for turbo engines. As the turbo tries to suck more air in, more and more air passes through the filter.

Now imagine that the filter is clogged, it becomes harder for air to pass through it, equivalent to you trying to breathe through a straw. Overtime this can damage the engine, and will damage your turbo. The engine will also need to work harder to deliver the same level of performance as it won’t be getting enough air.

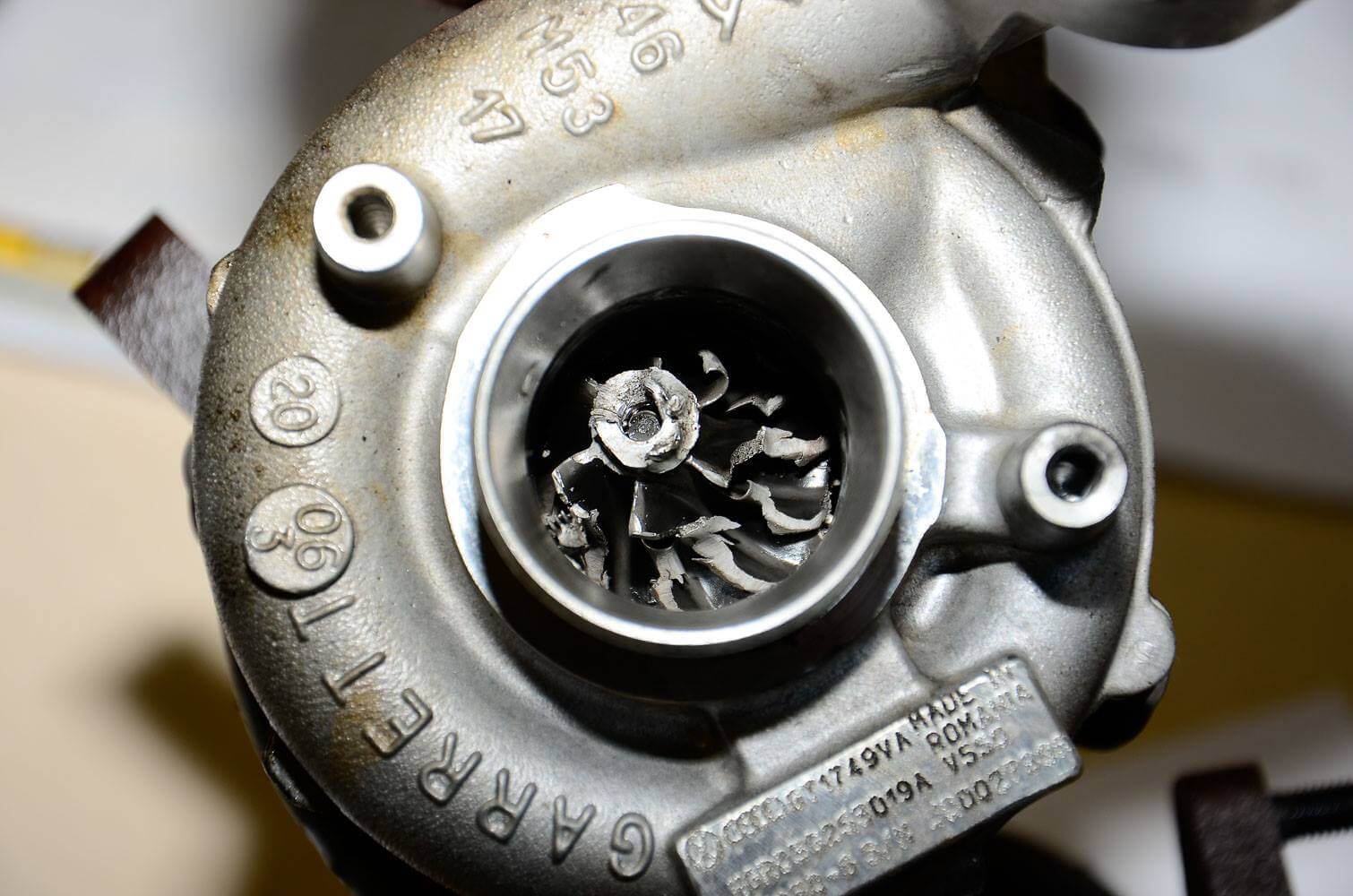

As the turbo continues to try and force more air through a clogged filter, the chance of debris getting through the filter increases. If a foreign object enters the turbo and starts to coat its blades or damage them, your turbo will fail. And if the debris gets past the turbo and into the engine, you may ruin the entire engine as well.

I’m sure that this all sounds scary and awful, but there is a simple way to prevent it. Change. Your. Filter. This is one of the simplest forms of preventative maintenance, air filters are cheap and easy to replace, while also being a key part of your engines intake system.

Sources: Ecogard, NGR Performance, Skilled Group, Q20, Autodata Trading, Mend Motor, NAPA Autoparts, Allstate, Premium Guard Filters